How Shoe Outsole Tooling is Made

How Shoe Outsole Tooling is Made

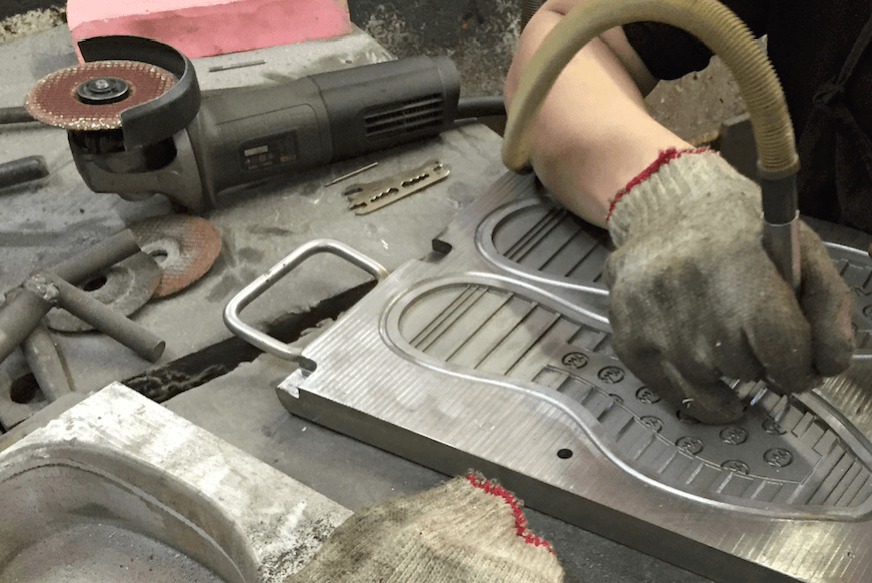

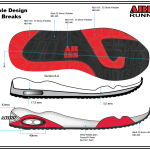

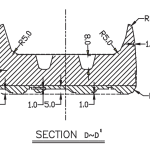

If you want to learn how shoe outsole tooling is made you are in the right place! All new outsole tooling starts with a designer’s drawing. The designer should have followed the last bottom outline to get the shape close to the final design. The shoe factory outsole technician will create a 2-D drawing for the designer to review. The shoe factory’s technician has a lasted upper so that he can draw a top net that fits the shoe correctly. Once the 2-D drawings are confirmed by the designer, mold factory will make a 3-D CAD drawing that will be used to cut a prototype part. Before any metal is cut, high density REN foam is cut so the designer and shoe factory can check all the details. The REN foam is soft when compared to metal and can be cut very quickly. The REN cutting machine running at high speed can cut the top, sides, and bottom of a new outsole design in just a few hours. Shoe tooling for midsoles and outsoles is made the same way.The Ultimate Shoe Material Textbook

Start with an in-depth study of material types available for modern shoemaking. Learn the technical details of material specifications. 195 pages and 300 color photos.

on sale $39.99