Shoe Making Process

Shoe Manufacturing Process

How are shoes made in factories? The manufacturing process for shoes is basically the same for all types of shoes. The sports shoe manufacturing process used to make a kids sneaker, Air Jordan™, or women’s high heel fashion shoe are very similar. Shoe factories around the world follow the basic steps to make a shoe.

The basic shoemaking steps are:

#1. Cutting upper parts

#2. Stitching shoe uppers

#3. Lasting and assembly

In this article, we will look at each of these factory processes for shoes. Of course, the number of operations is not 3. The number of operations is more like 30,000 depending on how you are counting.

Cutting Shoe Parts

The shoe production process starts with cutting the materials. Shoe parts are generally cut by steel dies in a hydraulic press. The cutting dies for shoe parts look like simple cookie cutters but they are very sharp. Every shoe part requires it’s own cutting die. Every part for every size needs its own die. These shoe parts are called the shoe pattern. To support the production of high volume shoes in popular sizes, often many die sets are required. The cutting dies are placed on the leather or fabric materials by hand, then the press closes to make the cuts.

Once the parts are prepared, the shoe factory workers will organize the parts into kits for the stitching department.

Stitching Shoe Parts

The upper is completely assembled with the reinforcing parts added and heat molded into shape. Toe caps and heel counters are formed and ready for the final assembly operations.

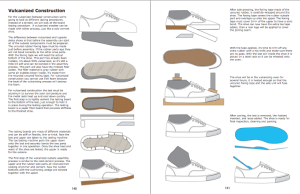

Shoe lasting and assembly Process

With the upper tight to the last, the outsole unit can be permanently cemented to the upper. During this process, the shoe travels inside a heat tunnel to dry the glue before the final bonding process. The last steps are QC and packing.

The process of making shoes is covered in great detail in the book How Shoes are Made. Inside How Shoes are Made you will find chapters on the cold cement process, vulcanized shoemaking processes, stitching, and outsole fabrication.