Sustainability in Footwear: 5 ways one start-up brand nails it

Is it possible to design sustainable footwear that is comfortable, fashionable, and helps to reduce global warming? Soléi Sea has found a way! Here are 5 eco-friendly ways they nailed it and 5 more footwear sustainability tips coming next week.

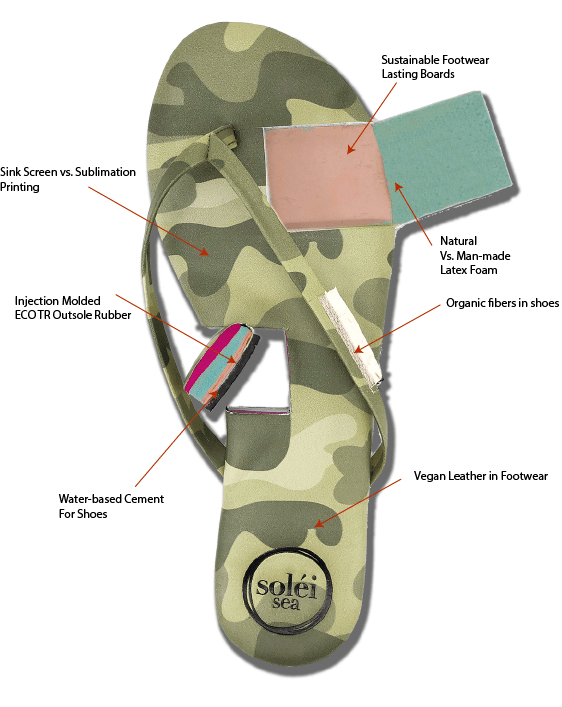

With initial sales soaring, hot, new, sandal brand Soléi Sea gives the simple flip-flop a sustainable makeover and proves that sustainability is indeed in style. Their production and design teams looked at every component in their new Indie flip-flop design and developed a strategy to improve the global footprint of their brand.

5 easy ways Soléi Sea nailed it…we give them a 5/5 in our sustainability update ♻️♻️♻️♻️♻️.

Sustainable Footwear Material Choices

Silk Screen vs. Sublimation Printing

The first thing we notice on the Soléi Sea sandal is the vivid camouflage color scheme. The sublimation process makes this colorful pattern possible. A computer printer deposits ink onto transfer paper; a heat press then transfers this special ink to the shoe material surface. Unlike traditional screen printing processes, there is no messy liquid ink or toxic solvents. Additionally, the sublimation process prints every color at once, reducing the handling required. The sublimation process requires a white base fabric and thus water-intensive chemical dyeing processes can be avoided.

Sustainable footwear lasting boards

The Soléi Sea sandals are made with a recycled paper lasting board. Now common in footwear, sustainable lasting board products are manufactured using recycled post-consumer raw materials and post-production scrap. In some cases, the sustainable, recycled product option can also be less expensive.

Natural vs. Human-made Latex Foam

This sandal is made with a cushioned latex foam. Latex foam for footwear can be made from 100% natural latex rubber sap or human-made synthetic latex. Care must be taken to ensure the natural latex sap is sustainably collected and the many native workers are fairly compensated. For latex, a middle ground is sought that combines both naturally sourced and human-made latex.

Vegan leather in footwear

Vegan leather is a human-made material. In the case of Soléi Sea, recycled polyester is used to make the microfiber backing fabric. The skin surface is a thin machine made film designed to accept the vivid colors of the sublimation printing. By choosing not to use animal leather, Soléi Sea is doing its part to reduce the intensive and negative environmental impacts of bovine leather production.

Organic fibers in shoes

Every single part of this classic sandal can have a sustainable makeover. Even the hidden reinforcements can be made with recycled polyester webbing or organic fiber cordage. In this case, the straps are reinforced with recycled fiber webbing.

ECO TR outsole rubber

Soléi Sea makes their sandal bottom with a recycled ECO TR rubber outsole. Because the factory makes the sole using an injection process, there is almost no manufacturing waste scraps. The Soléi Sea bottom supplier has a unique compound that reprocesses post-consumer and post-production materials into high-quality parts that do not look recycled.

Water-based cement for shoes

The sole unit and foam parts of the sandal are bonded together with water-based cement. Water-based cement is the more sustainable choice because it has no toxic solvents or volatile chemicals. Water-based shoe cement improves the worker’s health and the world’s environment. New advances in water-based bonding technology have improved its strength and reduced the energy required to cure the cement.

Sustainable shoemaking

To learn more about sustainable shoe making check out the Shoe Material Design Guide.

This book covers all types of shoe materials including leathers, rubbers, fabrics, and sustainable options.