RF Welding and Compression Molding for Shoes

RF Welding and Compression Molding for Shoes

Compression molding and RF welding both use heat and pressure to remold shoe materials. Welding can create unique design effects and save labor costs.

Welding Materials:

Man-made and natural materials can both be used but they require different tooling and RF welding techniques. Man-made materials such as mesh, PU, and foam can melt, mold, fuse, and stretch. Natural materials, such as leather and canvas, have some stretchability but will not remelt or fuse without the use of a synthetic backing material.

The factory will use EVA, PU, PE, and PVC foams to make the backing layers. These foams all accept the compression and with the right head and pressure, they will not rebound after RF welding.

RF Welding Tooling:

Logo welding equipment is usually Computer Numerical Control (CNC) cut from a soft, conductive, and rust free metal. Usually brass. Larger pressing tools can be CNC cut from flat aluminum sheets. Pressing tools that require a flat surface to press against can be made one-sided. The one-sided welding tool is limited in the dimensions it can create. A two-sided or “matched welding tool” can create 3D pockets and larger features. After molding, these pockets can be filled with foam or silicon.

Welding equipment:

Two classes of equipment are used to weld and emboss. The radio frequency or RF welder uses focused energy to locally heat the shoe materials and the machine comes in many sizes. A small, tabletop unit is great for logos, while a square meter sized machine is best for clothing and entire shoes.

Let’s look at some popular shoes and discuss how they are made.

Nike Air Zoom Pegasus ’92

The factory die-cuts the swoosh logo from flat TPU stock. A small RF welding machine is used to mold the logo’s 3D shape while simultaneously melting and bonding it to the fabric surface. The Air Pegasus logo is made by a similar process with higher heat to create the details. The Air Pegasus logo is made from metallic TPU film.

The tongue is completed by screen printing the logos and then welding the edge design. The tooling required to build this shoe is not expensive when compared to the outsole cost but must be CNC cut from brass.

Nike Flywire 3.0

TPU parts can be die-cut or laser cut for more complicated shapes.

Adidas Stan Smith Premium Leather

I really like what Adidas has done with this version of the classic Stan Smith. The Adidas designers have taken advantage of the Stan Smith’s toe cap pattern design to make a molded, one-piece heel, without any breaks. In this shoe design, Adidas shows the mold-ability of PU coated action leather. The heel logo detail is made by compressing the leather panel with a matched mold. When using a matched mold, the inner surface follows the outer surface to stretch the leather. After molding, the factory will fill the empty space with silicone gel or foam padding.

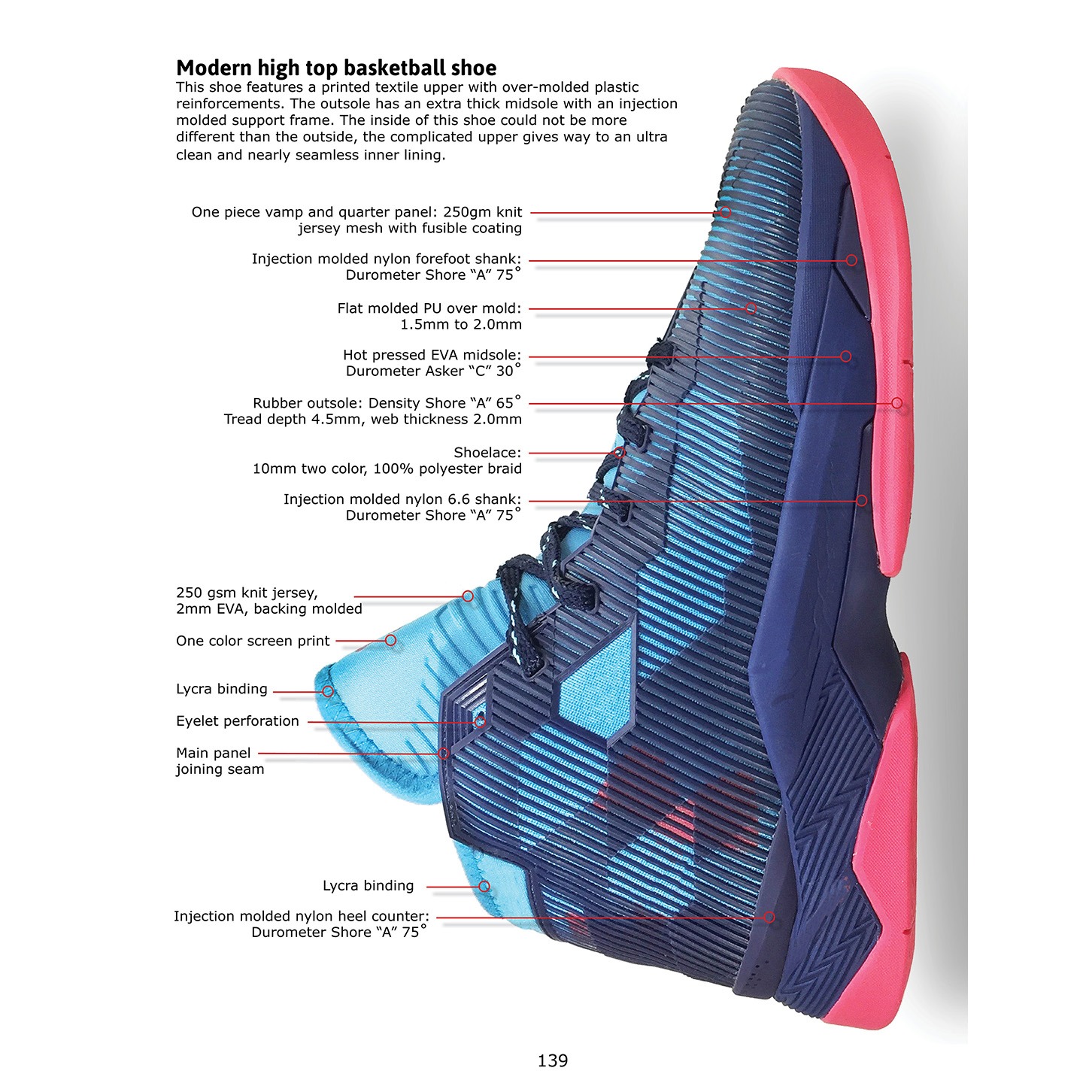

Shoe Material Design Guide

Do you want to be a professional shoe designer? You must learn how to select and specify footwear materials correctly. The Shoe Material Design Guide details all the shoe materials you will need to make modern athletic, classic casuals and high fashion footwear.

Each chapter covers a specific shoe material type. You will learn how each material is made, the options available to you, and how to specify the material correctly. Inside you will find chapters on leather, textiles, synthetics, laces, glue, reinforcements, hardware, logos, midsoles, outsoles, and more!

You will also find information on topics such as material testing, sustainable production, exotic materials and more. Written as a companion to our best selling How Shoes Are Made, The Shoe Material Design Guide digs deeper into the world of footwear materials and design. Softcover, 330 color photos, 28 chapters, 195 pages.