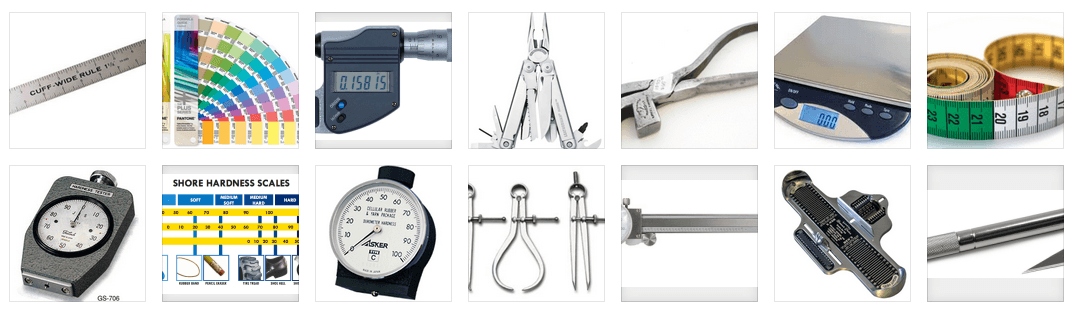

A Shoe Designer’s Tools

As a shoe designer or developer, you’re going to need some shoemaking tools to help you do your job. I have created a list of the common shoe designer tools that we use every day in our busy shoe design and development office. Some of these tools are specific to shoemaking, others are commonly found. In fact, almost all of these shoemaking tools can be found on Amazon.com.

Of course, you will need computers and drawing equipment but here is a list of the shoe designer tools that you might not commonly have but that you certainly need.

The Pantone color specification book is required for every shoe designer and developer. You will need to have a Pantone color book to communicate with the shoe factory and your customers exactly what color you want. The Pantone corporation color books are the industry standard for color matching. You will find that every shoe factory will have a Pantone book so it’s easy for you to reference a color. Without the Pantone book, it’s almost impossible to match colors correctly with your overseas factories. They are expensive, you can share one in your office. This is a must-have shoe designer’s tool. You can get these from Amazon.

The Pantone color specification book is required for every shoe designer and developer. You will need to have a Pantone color book to communicate with the shoe factory and your customers exactly what color you want. The Pantone corporation color books are the industry standard for color matching. You will find that every shoe factory will have a Pantone book so it’s easy for you to reference a color. Without the Pantone book, it’s almost impossible to match colors correctly with your overseas factories. They are expensive, you can share one in your office. This is a must-have shoe designer’s tool. You can get these from Amazon.

A small steel ruler is very useful for measuring all the shoe parts. Make sure that the end of the ruler is cut off so it starts at zero so you can measure the inside of the shoe collar height by pushing the ruler into the bottom of the shoe.

A small steel ruler is very useful for measuring all the shoe parts. Make sure that the end of the ruler is cut off so it starts at zero so you can measure the inside of the shoe collar height by pushing the ruler into the bottom of the shoe.

A Leatherman multi-tool is a very useful piece of equipment with its blades for slicing open seams and its pliers for taking parts off. The serrated blade and saw blade are very useful for cutting sections out of sample shoes.

Shoemaking lasting pliers are also a very useful tool to have around. In the shoe factory, they are used to pull the edges of the material down on the last and then tack it down with a hammer part. As a developer, you will often use this tool to pull a shoe apart and see what’s inside.

Shoemaking lasting pliers are also a very useful tool to have around. In the shoe factory, they are used to pull the edges of the material down on the last and then tack it down with a hammer part. As a developer, you will often use this tool to pull a shoe apart and see what’s inside.

A gram scale is a very useful tool in the creation of high-tech performance footwear. We quite often will have issues with subcomponents and measure each piece, part by part, to make sure that we’re making the lightest piece of footwear we can make.

We always have a flexible measuring tape on hand for measuring around shoe lasts and for measuring different shoe components. A flexible measuring tape is very useful for measuring feet and ankles.

A Durometer tester is used to test the hardness of any rubber or plastic shoe component. For testing shoe rubber and plastic you need a Shore scale “A” tester. The Durometer tester’s bottom measuring pin is simply pressed against the material. The Durometer tester will give you a reading of the density of the material. Try to test in flat spots and take several readings for each shoe part you are checking.

An Asker “C” scale Durometer tester is used to test the hardness of any foam shoe components. The Durometer tester will give you a reading of the density of the material. Try to test in flat spots, take several readings for each shoe part you are checking. For foam, try to cut the parts so you can test the center of the foam. EVA foam skin may give you a harder reading. A standard EVA midsole may be 55˚, a soft footbed 35˚.

A set of adjustable dividers is very useful in designing and developing footwear. We use the dividers to check critical measurements of lasts and different components that may be hard to reach. A pair of dividers is a very useful tool when comparing dimensions from one sample to another. For working on oversize boot lasts you will need a set.

A pair of dial calipers or digital calipers is also very useful in making shoes. We use calipers every day to measure the width of small shoe components.

A pair of dial calipers or digital calipers is also very useful in making shoes. We use calipers every day to measure the width of small shoe components.

A Brannock device. You’ve seen this tool in every shoe store. This is the standard for measuring feet. If you’re developing footwear, you must have a Brannok device in your office. When a tester says a shoe fits loose or tight, the first thing you need to do is measure their feet against the machine. Also, use your flexible measuring tape to measure feet.

An X-Acto knife is also an indispensable tool for cutting material swatches, for opening up shoes and cutting open seams. A very sharp hobby knife is a useful tool.

An X-Acto knife is also an indispensable tool for cutting material swatches, for opening up shoes and cutting open seams. A very sharp hobby knife is a useful tool.

A 3-D printer can also be a very useful tool in the shoe development office. The 3-D printer can quickly create small plastic pieces that you might use for lace pulls or hardware. We have found the small 3-D printer is very practical and saves time and money. The new 3-D printers can also print with flexible plastic materials. With the larger machine, you can also print outsole components.

A micrometer is a very helpful tool to have in your shoe development office. We use this for checking the thickness of leather products or any synthetic material. We use a micrometer almost every day to confirm that the materials in the sample shoe match the product specification.

A micrometer is a very helpful tool to have in your shoe development office. We use this for checking the thickness of leather products or any synthetic material. We use a micrometer almost every day to confirm that the materials in the sample shoe match the product specification.

A profile gauge is nice to have around when you are checking lasts. It’s useful for checking complex curves quickly. While not a common tool, we use this when we are working up a new last or checking that a midsole is following the last bottom curve correctly.

A profile gauge is nice to have around when you are checking lasts. It’s useful for checking complex curves quickly. While not a common tool, we use this when we are working up a new last or checking that a midsole is following the last bottom curve correctly.

You can buy most of these tools here: Amazon.