How Shoe Lasts are Made By Tsubo

Here is another great shoe making video from the Tsubo shoe company. This shows how shoe lasts are made. They show in a nice step by step video what it takes to make a set of production shoe lasts. You can see the care they take in this process. It’s very important as these lasts will be the foundation of the finished shoes.

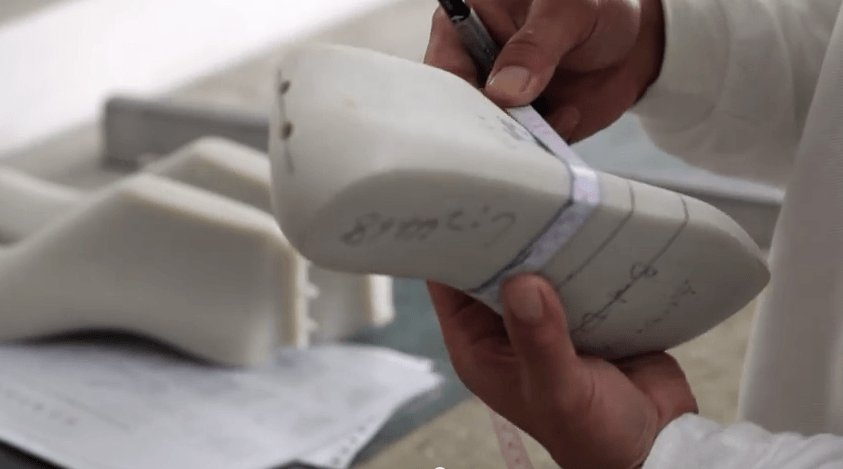

Here you can see they are cutting the pattern templates used to fine tune the shape of each production shoe last. The templates are used to make sure the heel back curve and toe shape are correct. The foot shaped template is called the bottom gauge. You need this to confirm the length and width of the last.

This is really how shoe lasts are made. They shape the last they start with a injection molded blank roughly the right shape. This blank saves the factory time and money as the shape the last. The left over cuttings can also be recycled. The lasts are quickly rough cut then finely finished using a second machine. This takes just a few minutes

In this video they are making plastic hinged lasts, the hinge allows the shoe last to be slid into and removed for the upper without over stretching or damaging the shoe material.