DIY Quilted Sneakers:

A Complete Step-by-Step Guide

Crafting your own quilted sneakers is both an artistic and functional project. Whether you’re a shoemaking enthusiast, sewing superstar, or a quilting hobbyist, this guide walks you through the entire process of creating a custom pair of sneakers using the Quilter’s Sneaker Kit for DIY Beginners or other DIY build kits we offer.

You will need basic sewing skills, quilting materials, and household tools. By following this comprehensive guide, you’ll learn how to combine your sewing skills and quilting techniques with sneaker construction to create a pair of truly unique and functional shoes.

In this guide, we explain two different construction options: the “Quick Build” method and the more durable “Glue-N-Stitch” process. We cover planning, quilting, construction, and finishing steps.

"Sew Easy" Quilted Sneaker Kit

Gathering Tools and Materials

Before you begin, make sure you have everything you need at hand. Having a dedicated workspace, good lighting, and the right materials makes a huge difference.

Essential Tools and Supplies you will need to make a quilted sneaker :

- Shoemakers Academy “Sew Easy” Sneaker Quilters Kit

Items included in the kit:

Rubber Outsoles

Lasting Boards: Pink

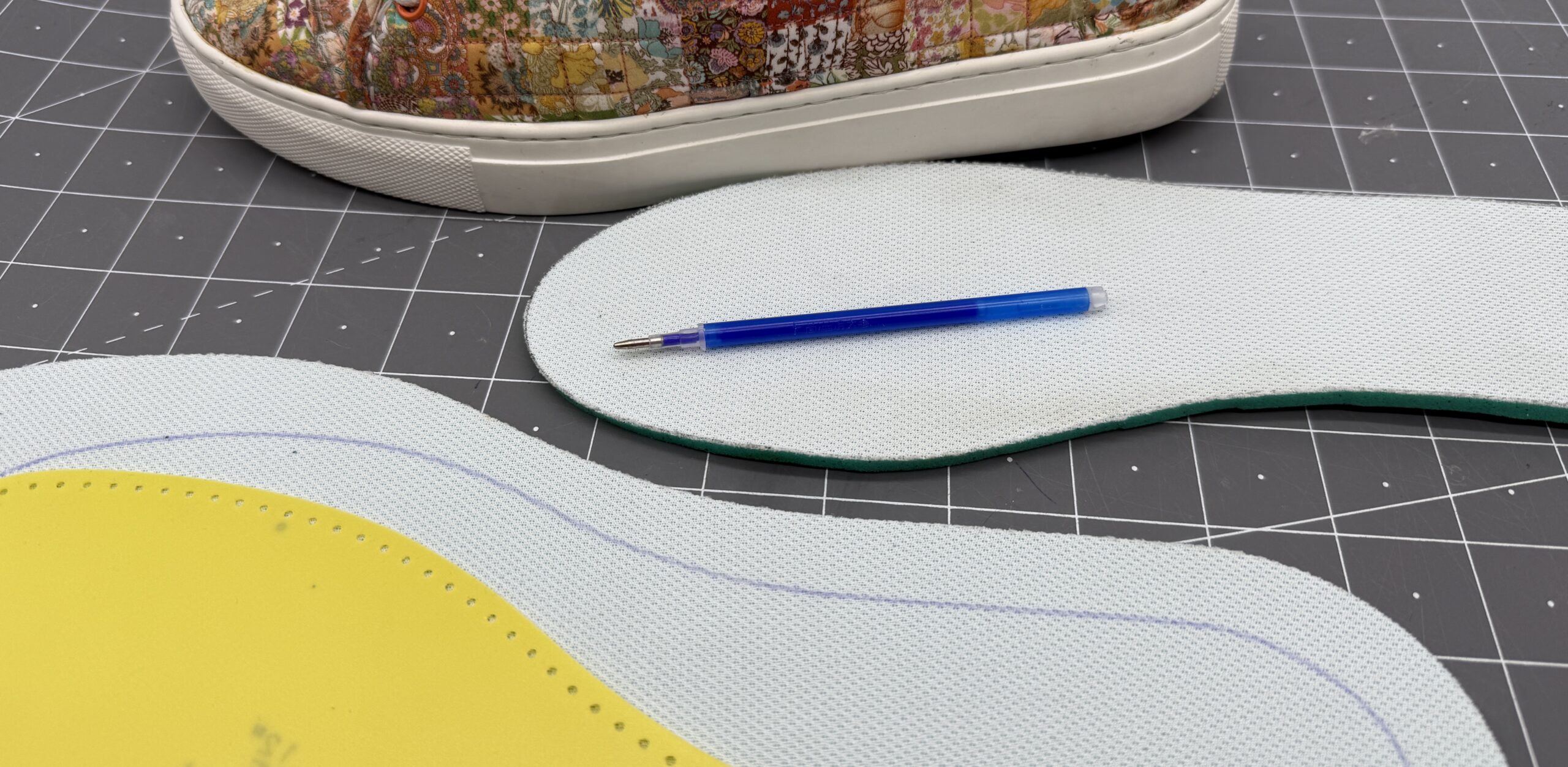

Memory Foam Footbeds: white mesh with green foam

Sole Stitching Awl needle with wooden handle

Waxed Thread: White, 30 feet

Sneaker pattern template

Heat-erasable marking pen: Blue

You will also need:

- Fat quarter or fabric scraps to quilt (approx.1 yard total) 18” x 22” inches

- Fat quarter or fabric scraps for lining (approx.1 yard total) 18” x 22” inches

- Some extra fabric that will not be quilted. to decorate or cover the footbed

- Foam padding/backing fabric/batting (approx.1 yard total – try this from Shoemakers Academy)

- Shoelaces (flat or round) approx. 59″ for low cut and 63″ for high top

- Eyelet setting tool & eyelets (available from Shoemakers Academy)

- 5mm eyelet hole punch (available from Shoemakers Academy)

- Sewing machine

- Needles (hand sewing, quilting, and large ball point)

- Scissors or rotary cutter

- Cutting mat

- Double-stick tape

- Iron + pressing cloth

- PU Contact Cement: (we like Barge)

- Bias tape or edge binding (optional)

- Crochet hook or wire hook (optional for channel stitching)

Planning & Template Preparation for your Quilted Sneakers

Step 1: Designing your shoe

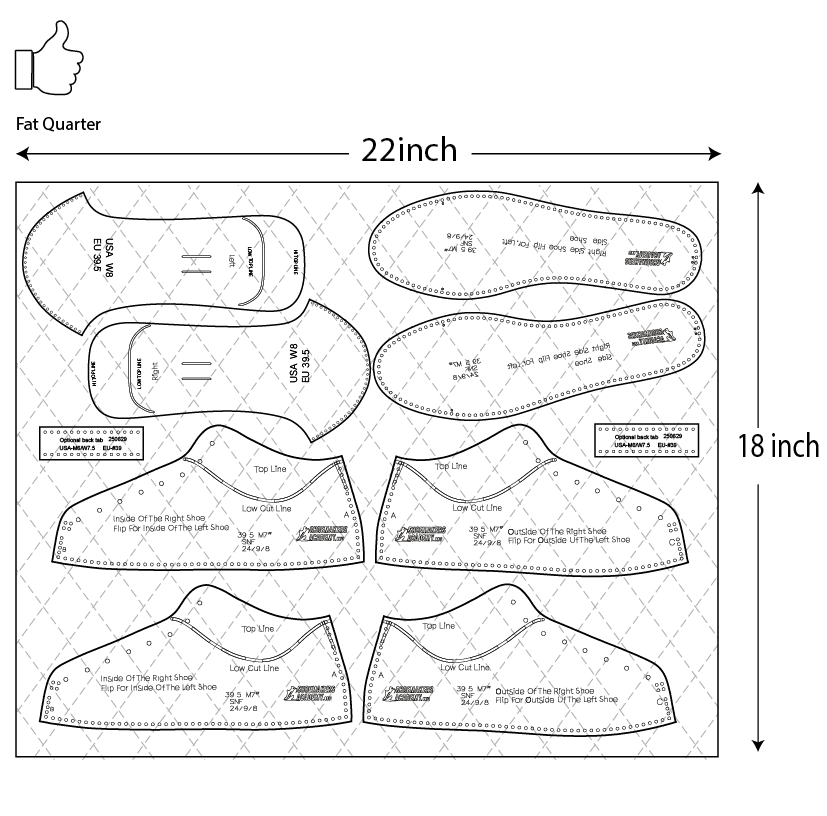

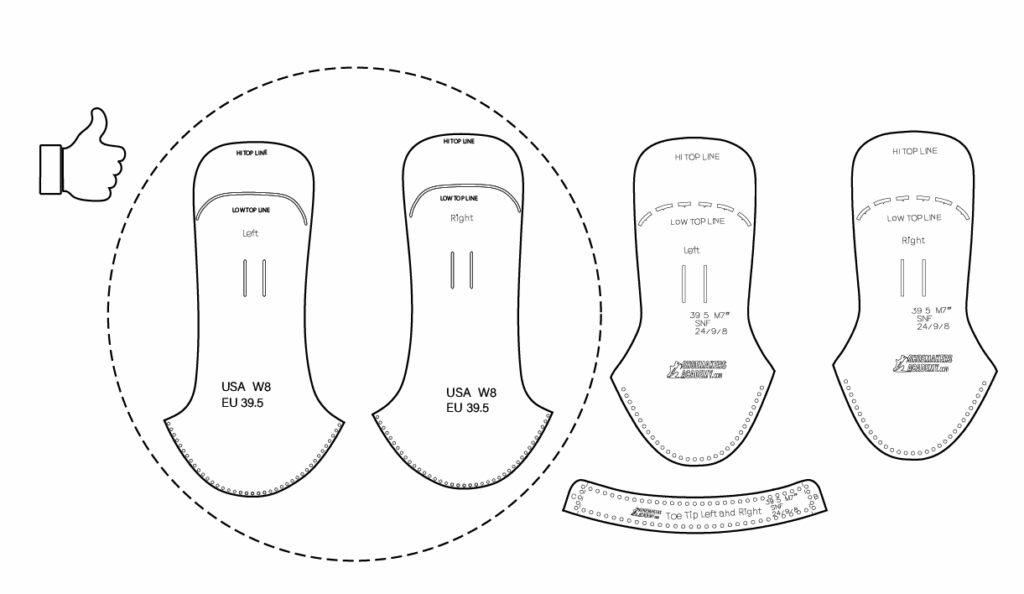

The Shoemakers Academy sneaker template pattern offers two tongue styles and two collar heights. The kit includes the tongue patterns, side panels, footbed pattern, and may include a back strap pattern.

- One-Piece Tongue/Toe: Gives quilted shoes a sleek and continuous upper look.

- Two-Piece Tongue/Toe: Gives leather shoes a cleaner assembly & easy gluing

- High top: The classic style.

- Low cut: Sleek lower cut.

Step 2: Arrange your template

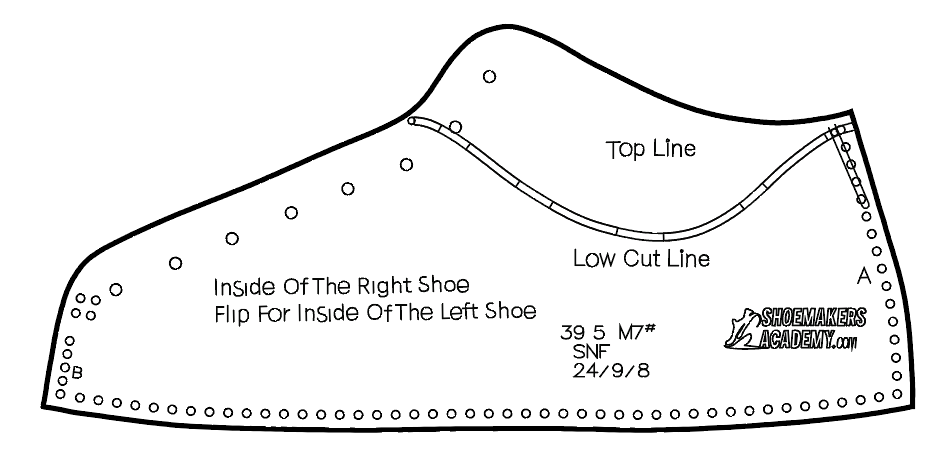

Your precut sneaker template is already 100% to scale, but does NOT have any seam allowances added. The perforations on the pattern are for leather and hand sewing, but you can also use them for a stitching guide. The larger holes on the pattern are for your shoe lace eyelets.

- Choose a low-cut or high-top sneaker. Use the long tongue pattern for high-tops. Short tongue line for the low-cut.

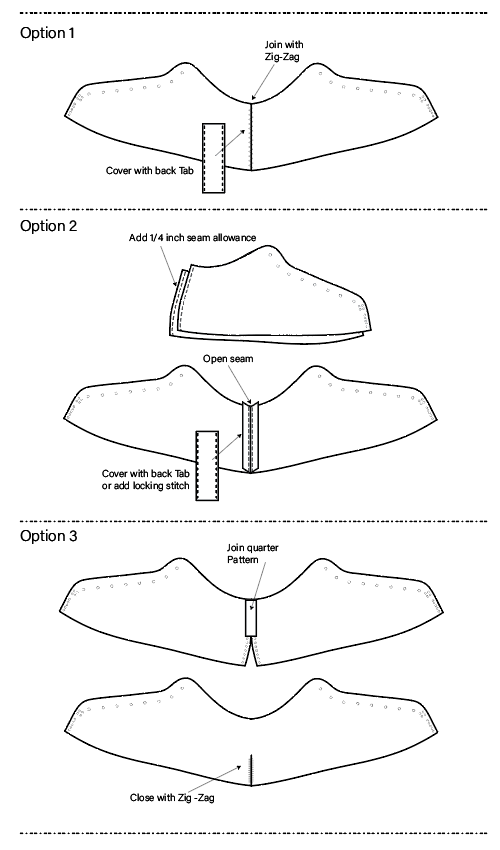

Back Seam: You have three options to create your back seam.

- To create a curved heel seam: zig-zag the parts together and cover with flat binding tape.

- To create a curved heel seam: add 1/4 inch seam allowance, then join the parts with the outside surface fabrics facing out. Turn out the seam, then cover with binding tape or a back tab.

- Combine the pattern and cut as one piece: zig-zag the bottom 1/2″ of the seam to create the curve. The zig-zag will be hidden below the outsole.

Step 3: Plan, Quilt, Design, and Layout

Plan your design visually before cutting:

- Choose quilt motif: diamonds, crosshatch, channel, etc.

- Consider the color contrast between the toe, quarters, and tongue.

- Have fun, be creative! Consider symmetry across the left and right shoes.

- Plan how the batting will lie beneath decorative stitching.

- Determine thread colors that will complement your design.

- Consider your binding, shoelace, and eyelet colors.

- Don’t forget to plan the fabric design for the top of your footbed.

Sewing Your Quilted Fabric Panels

Step 4: Prepare Quilt Sandwich

If you are attending a class, preparing your quilted panel will be your “homework.” You will need to have this ready. Please confirm with your teacher. You will need a fat quarter of quilted fabric and some extra non-quilted fabric if you want to cover the footbed.

- Layer exterior fabric top, foam/batting (center), and lining fabric (optional for this step).

- Baste layers together using spray adhesive or pins.

- Underlayment (Recommended if you would like to build a sturdy shoe for everyday wear.)

- Lining Fabric – It’s important to select a comfortable, colorfast fabric. This lining may be included in your quilt, OR not, depending on how you plan to finish your edges.

At this stage, you may add reinforcements or underlayment to the exterior fabric.

If you don’t plan to quilt through your lining, you may add heel stiffeners and toe reinforcements later.

Step 5: Quilt Your Panels

- Stitch straight lines, grids, or chevrons using a machine or by hand.

- Keep stitch spacing

- Press panels gently to flatten.

- Be creative, follow your shoe design or fabric pattern.

Step 6: Trace & Cut Shoe Pattern Pieces

- Trace pattern pieces on quilted panel (batting side).

- Use the RIGHT-side pattern to create LEFT shoe panels and vice versa.

You must mark the parts, as you will have 4 different pieces. - If you joined your side panel at the heel, make sure you have marked the left and right.

- If you plan to edge bind, overlock, or use a merrowed technique, then NO seam allowance is required.

- If you plan to turn out the tongue and quarter edges, then add at least a ¼-inch seam allowance to the long edges of the side panels and tongue.

- Make a count, you should have 4 quarters and two tongues.

- The pattern comes with an optional pieces for the back tab and footbed cover.

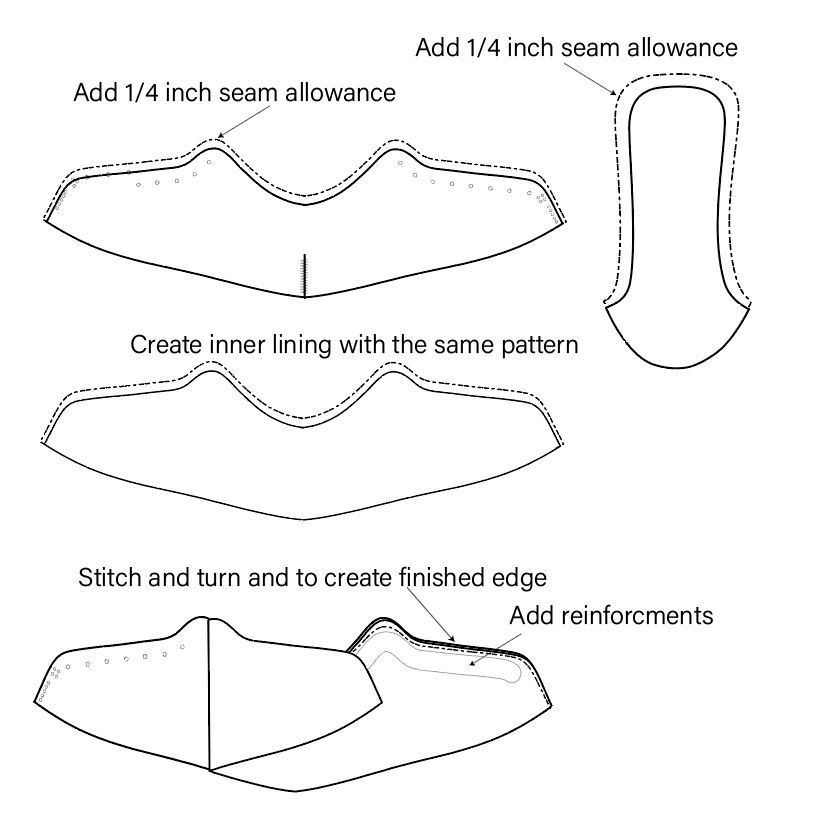

Step 7: Add Lining and Edge Bindings to Panels

- If you did not quilt your lining, now it’s time to add reinforcements or underlayment.

- Shoemakers Academy offers heat-moldable toe-puff and heel-counter reinforcement materials.

- These can be installed flat, then heat-molded into shape later with an iron or hair dryer.

- Attach the lining by sewing around the edges of the side quarter and tongue.

- Turn the collar lining out over the top collar, then turn the tongue out.

- Iron these parts flat. You may choose to add fusable backing or a top stitch around the edge.

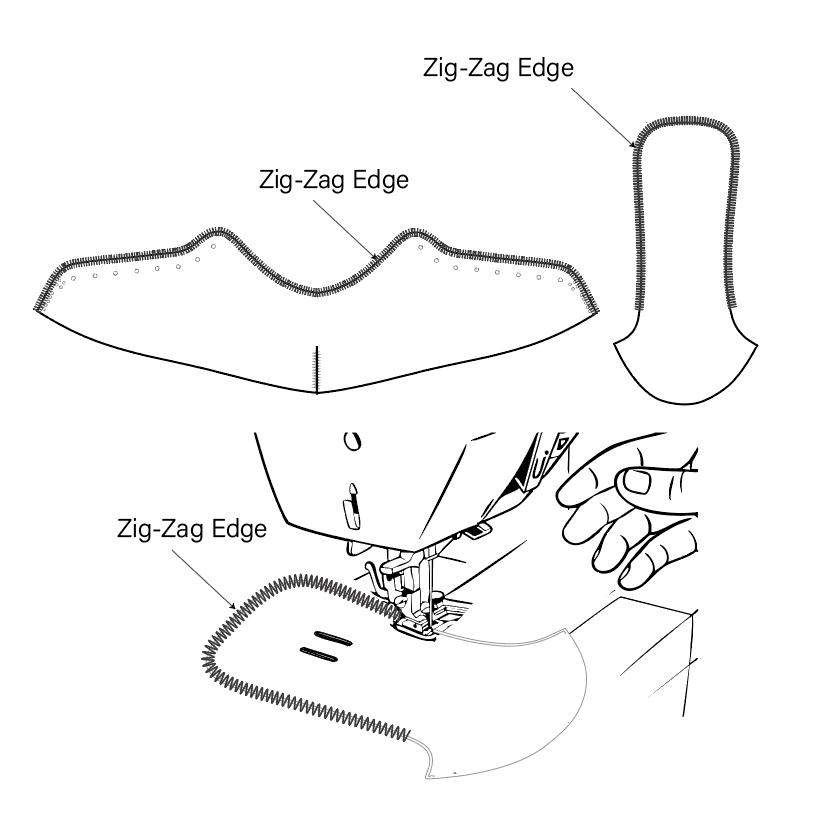

- If you plan to edge bind, overlock, or use a merrowed technique, then NO seam allowance is required.

- If you plan to turn out the tongue and quarter edges, then add at least ¼ ” seam allowance to the long edges of the side panels and tongue.

Turned Out Edge

Attach the lining to your quilted sneaker upper. Collect your quilted parts and your lining.

Let’s sew them together and turn out our seam for a neat finished edge.

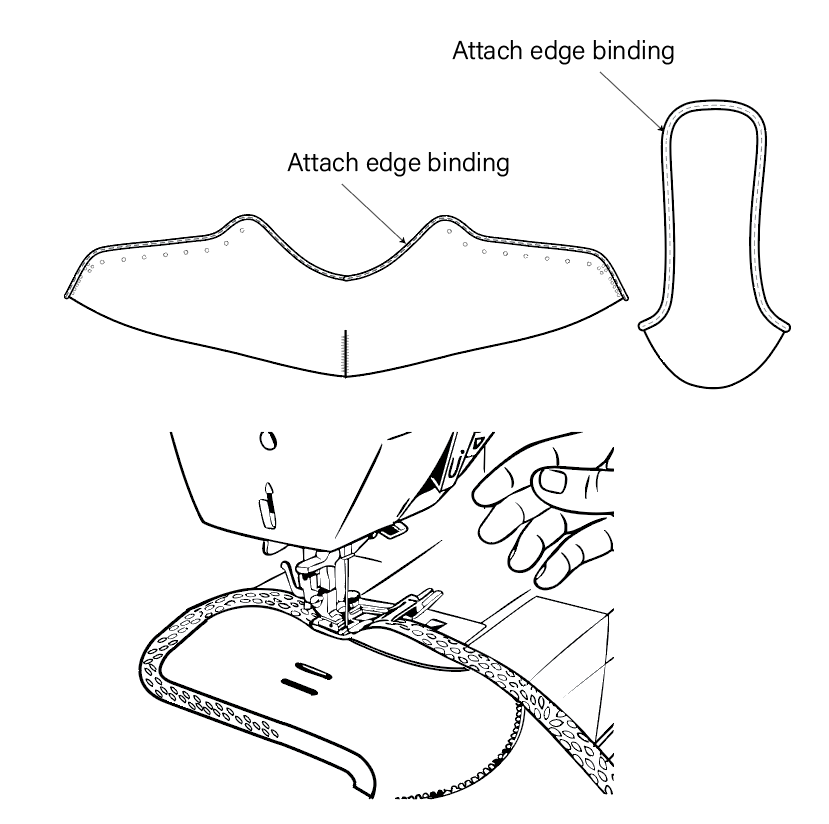

Binding Edge

Sewing a binding edge is a great way to add some flare. Let’s see how easy it is.

Add Reinforcements

You can add some structure with some non-woven interface materials and some heat moldable toe puff and heel counters.

Shoe Reinforcement Interface Fabric

white Non-Woven .5mm

Overlock or merrowed technique

Easy to make rolled edge

Binding edge

Eyelets, Tabs, and Prepping for Sneaker Construction

Step 8: Install Eyelets

Before you start, grab some scraps of the quilted fabric to practice punching holes and setting eyelets. Make sure your lining is attached before you start the eyelets. Also, you will need to use a hammer. If you don’t own eyelets you can get a kit here.

- Use the pattern quarter templates to locate and mark the eyelet locations.

- Punch the 5 mm holes using the template markings.

- With the lining face up, insert the longer eyelet part into the hole.

- With the lining face up, place the backing ring onto the rivet shaft.

- Insert the setting base from the back. Carefully hammer the setting tool.

- Tap gently, increasing the pressure until the eyelet shaft is folded over the back.

- Remove the setting tool to check your work. The rivet back should be smooth with no split edges.

- Repeat to complete all the eyelets.

Step 9: Add Optional Shoelace Keepers

You have a few options to make a unique lace keeper.

- Sewn lace keeper: Cut two 1.5″ squares from scraps. Fold and press edges. Sew to the tongue, use the template as your guide.

- Make two parallel cuts and leave the raw edges. Use the template as your guide.

- Use a buttonhole attachment if your machine has one.

Let's Assemble The Upper

Step 10: Quick Build Assembly

First, let’s sew the quarter panels to the outsole, then we will finish with the toe. You will be using the sewing awl or a speedy stitcher if you have one.

- Make sure you have the correct parts to match the left and right outsoles

Channel Stitching the side panel to the sole

For this step, you will need the heavy waxed thread included in your kit and the sole stitching awl.

- Using the included waxed thread, make 3 loops around the outsole for the correct length.

- Begin at the front of the quarter panel on the outside of the shoe.

- With the needle threaded, punch the sewing awl into the stitching groove.

- From inside the shoe, pull 1/3 of the thread inside. Withdraw the awl.

This will be your bobbin thread. - To make your first stitch, push the threaded awl into the groove, then,

to create the loop, withdraw the needle ½ way. - Now pull the bobbin thread through the loop to make the stitch.

- Withdraw the needle and pull the thread to tighten the stitch.

- Be careful not to twist the awl as you sew.

- Repeat around the entire shoe.

- To secure the final stitch, pull the thread end inside the shoe, then knot and trim.

Here is the full one hour video

showing the complete sole stitching operation.

Making a Stronger Shoe

The Shoemakers Academy kit includes the option to make stronger shoes. Glue-N-Stich process: For this method, you will first sew the upper parts to the pink lasting board, then glue this assembly into the outsole. Next, secure the upper to the outsole with the channel stitching process. This method requires more time to make but produces a more durable and supportive shoe, more suitable and comfortable for everyday wear.

- Punch holes around the perimeter of the pink lasting board.

- Use the pattern to mark guide marks on the bottom edge of the upper.

- Optional – If you have thicker upper materials, you can pre-punch the stitching holes on the upper.

- Start stitching at the heel midpoint.

It’s critical to center the upper on the center line of the lasting board heel. - Leave a 1/8″ gap from the material edge to the board edge.

- Keep the thread tension loose to allow fitting.

- Sew all the way around the lasting board.

Glueing The Outsole

- Test fit the upper and the outsole.

- Use the erasable marking pen to mark the glue line.

- Clean the outsole with acetone, cement thinner, or hot water.

- Apply cement to both the upper and the outsole.

- Allow the glue to dry; the glue should be tacky with no wet spots.

- Carefully land the heel of the upper into the heel of the outsole.

- Working with one hand inside the shoe, press the upper and outsole together.

- Once the glue has set, complete the channel-sole stitching.

Finishing Touches

Step 14: Footbed & Fit Test

Now it’s time for the finishing touches! Collect your shoe laces and footbed foam.

- Trim footbed edges

- For a firmer footbed, trim the pink lasting board and place it (or glue it) under the footbed.

- Choose a colorful shoe lace to complement your style (flat, round, elastic) and a fancy lacing technique to finish up your shoes.

- Congratulations! You did it!